WCMBR-(U) type shipboard membrane-based domestic sewage treatment device

- Product Description

-

- Commodity name: WCMBR-(U) type shipboard membrane-based domestic sewage treatment device

- Commodity ID: 1398257521268510720

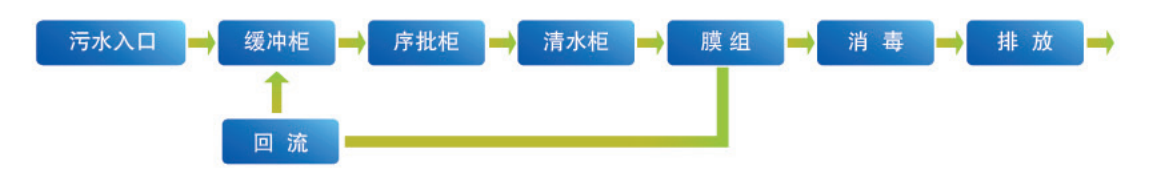

This device uses a Sequencing Batch Reactor (SBR) membrane process to treat organic pollutants. Wastewater first enters a buffer tank to adapt to biological treatment. This tank can accommodate three times the peak hydraulic load. When the water level in the tank reaches the starting level, it is transferred to an SBR tank with soft packing material for SBR biological contact oxidation treatment. The treated water enters a clear water tank. When a certain water level is reached, it enters the membrane module or is directly discharged. The effluent filtered by the membrane module is disinfected with ozone or ultraviolet light before being discharged overboard, meeting the requirements of IMO MEPC.159(55). This product has obtained CCS type approval certificates, IMO certificates, USCG, ABS and EC certificates, and national invention and utility model patent certificates. In 2008, it was included in the Jiangsu Provincial Science and Technology Achievements Transformation Special Fund Project. Features: It adopts an external membrane, which is convenient for replacement and maintenance; various measures are adopted to extend the service life of the membrane; a buffer tank and standby mode are adopted to meet the requirements of three times the peak load; ozone disinfection or ultraviolet disinfection is adopted to avoid secondary pollution and achieve good decolorization; PLC program control is adopted for more convenient control and maintenance; SBR technology is adopted, with a high sludge load rate, more thorough treatment, and very little sludge discharge; an automatic sleep program is set to adapt to zero-load conditions; multiple treatment methods are set to meet the requirements of different sea areas; this device can also be used to treat concentrated wastewater collected by vacuum. Due to the relatively small hydraulic load, the membrane method is more adaptable.

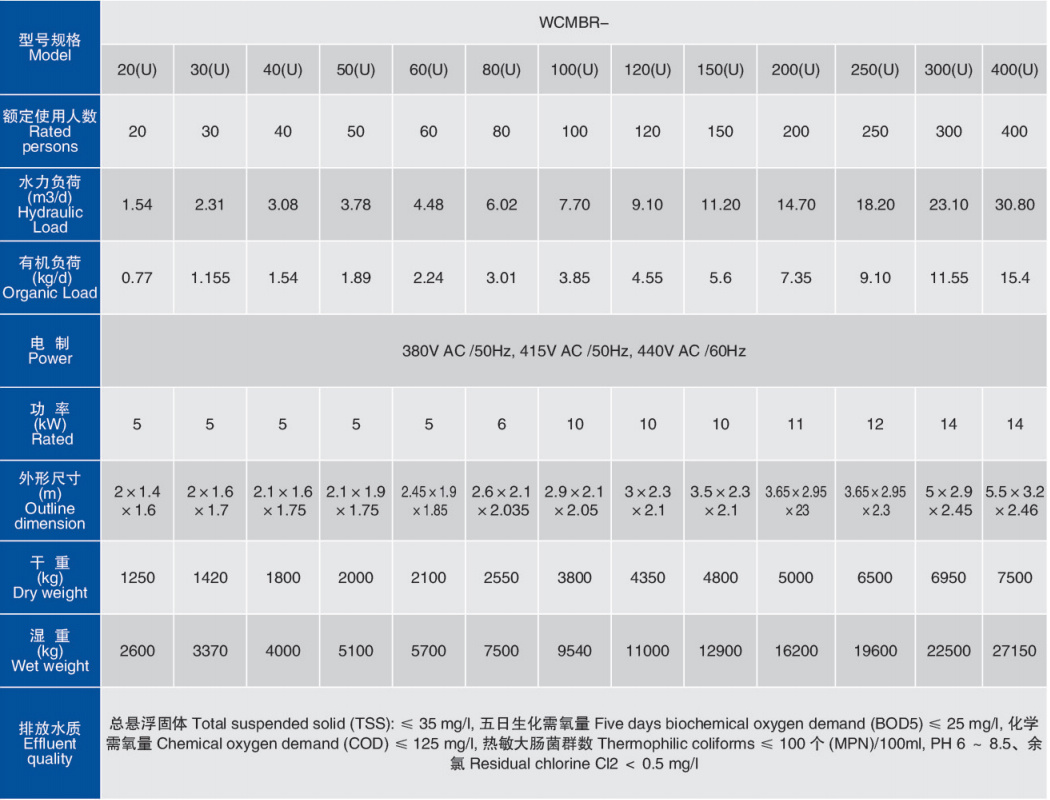

PurposeThis device is suitable for treating domestic sewage generated in ship personnel toilets. The discharge water indicators fully meet the discharge standards of IMO.MEPC227(64) resolution and can be directly discharged overboard. This device has been type-approved by CCS, ABS, BV, EC, and USCG.Principle OverviewThis device uses a batch-membrane process to treat organic pollutants. The treatment process is as follows: Domestic sewage first enters the buffer tank to adapt to the biochemical treatment process. At the same time, this tank can accommodate three times the peak hydraulic load. When the liquid level in the tank reaches the middle position, the shredding pump starts, transferring the sewage to the batch tank with soft packing material for batch contact oxidation and biochemical treatment. The treated sewage is transferred to the clear water tank by the process pump. When the liquid level reaches the middle position, the discharge pump starts, pumping the treated water into the membrane unit or directly discharging it. After filtration by the membrane unit, the discharged water is disinfected and discharged overboard. According to the rules of the designated sea area stipulated in the international convention, batch treatment or membrane treatment can be flexibly used.Features1. Uses an external membrane for convenient replacement and maintenance;2. A buffer tank and standby mode are set to meet the requirements of three times the peak load of black water;3. Uses ultraviolet disinfection to avoid secondary pollution;4. Uses PLC program control for more convenient maintenance;5. Uses a batch process, with a high sludge load rate, more thorough treatment, and less sludge discharge;6. An automatic sleep program is set to adapt to zero-load conditions;7. Three cleaning methods are adopted: compressed air automatic flushing, pressure water backwashing, and chemical immersion cleaning, extending the service life of the membrane;8. Multiple treatment methods are provided to meet the requirements of different sea areas;Main Technical Parameters

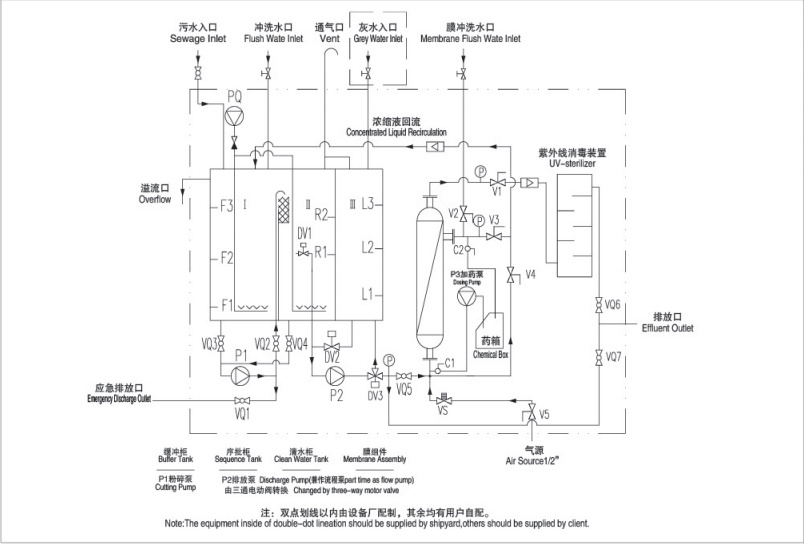

Domestic sewage first enters the buffer tank to adapt to the biochemical treatment process. At the same time, this tank can accommodate three times the peak hydraulic load. When the liquid level in the tank reaches the middle position, the shredding pump starts, transferring the sewage to the batch tank with soft packing material for batch contact oxidation and biochemical treatment. The treated sewage is transferred to the clear water tank by the process pump. When the liquid level reaches the middle position, the discharge pump starts, pumping the treated water into the membrane unit or directly discharging it. After filtration by the membrane unit, the discharged water is disinfected and discharged overboard. According to the rules of the designated sea area stipulated in the international convention, batch treatment or membrane treatment can be flexibly used.Features1. Uses an external membrane for convenient replacement and maintenance;2. A buffer tank and standby mode are set to meet the requirements of three times the peak load of black water;3. Uses ultraviolet disinfection to avoid secondary pollution;4. Uses PLC program control for more convenient maintenance;5. Uses a batch process, with a high sludge load rate, more thorough treatment, and less sludge discharge;6. An automatic sleep program is set to adapt to zero-load conditions;7. Three cleaning methods are adopted: compressed air automatic flushing, pressure water backwashing, and chemical immersion cleaning, extending the service life of the membrane;8. Multiple treatment methods are provided to meet the requirements of different sea areas;Main Technical Parameters System Diagram

System Diagram Structural Form

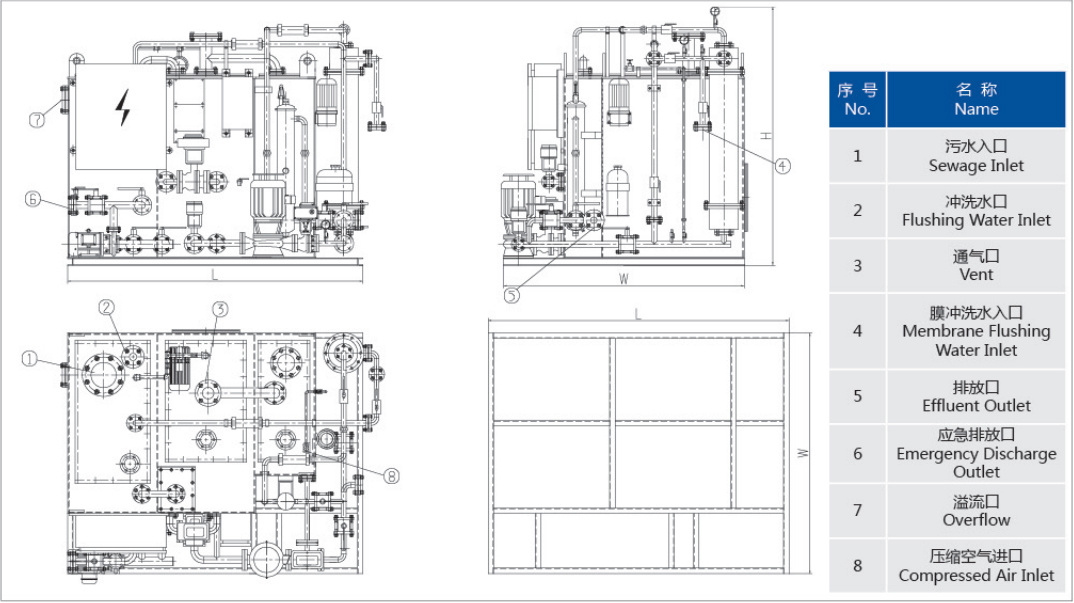

Structural Form

Related products

Get a free product quote